AION

2021.09

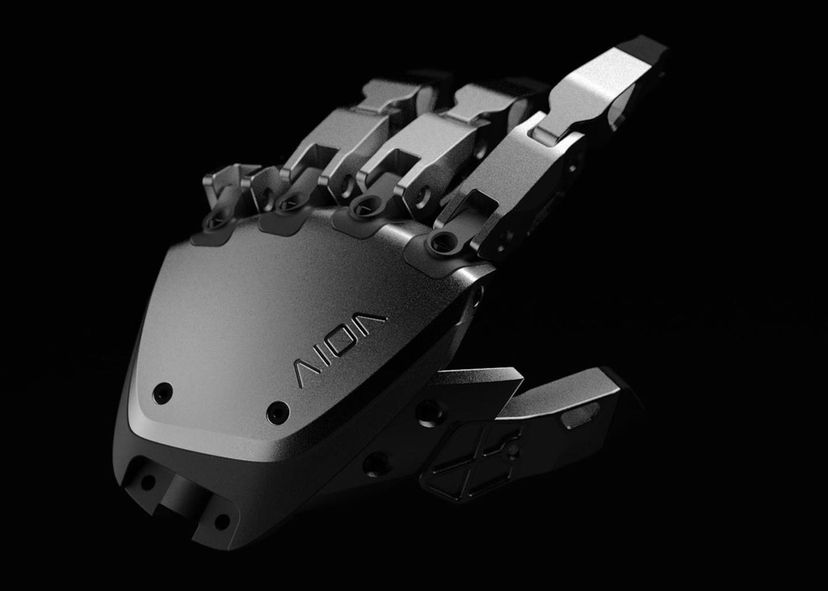

The AION hand project is a carefully crafted solution designed to offer a high-performance, low-cost alternative to traditional myoelectric prosthetics. At its core this project places industrial design at the forefront, working closely with amputees to ensure the hand’s design is both functional and desirable. The team focused on creating a prosthetic that not only met the technical requirements but also addressed the user’s needs, ensuring comfort and usability. By incorporating feedback directly from the amputee community, the design was refined through simple, accessible solutions. This allowed us to quickly test prototypes with real users before moving on to more intricate internal mechanics. The result is a prosthetic that is not only practical but also approachable, making it a viable option for those seeking a high-powered solution at an affordable price.

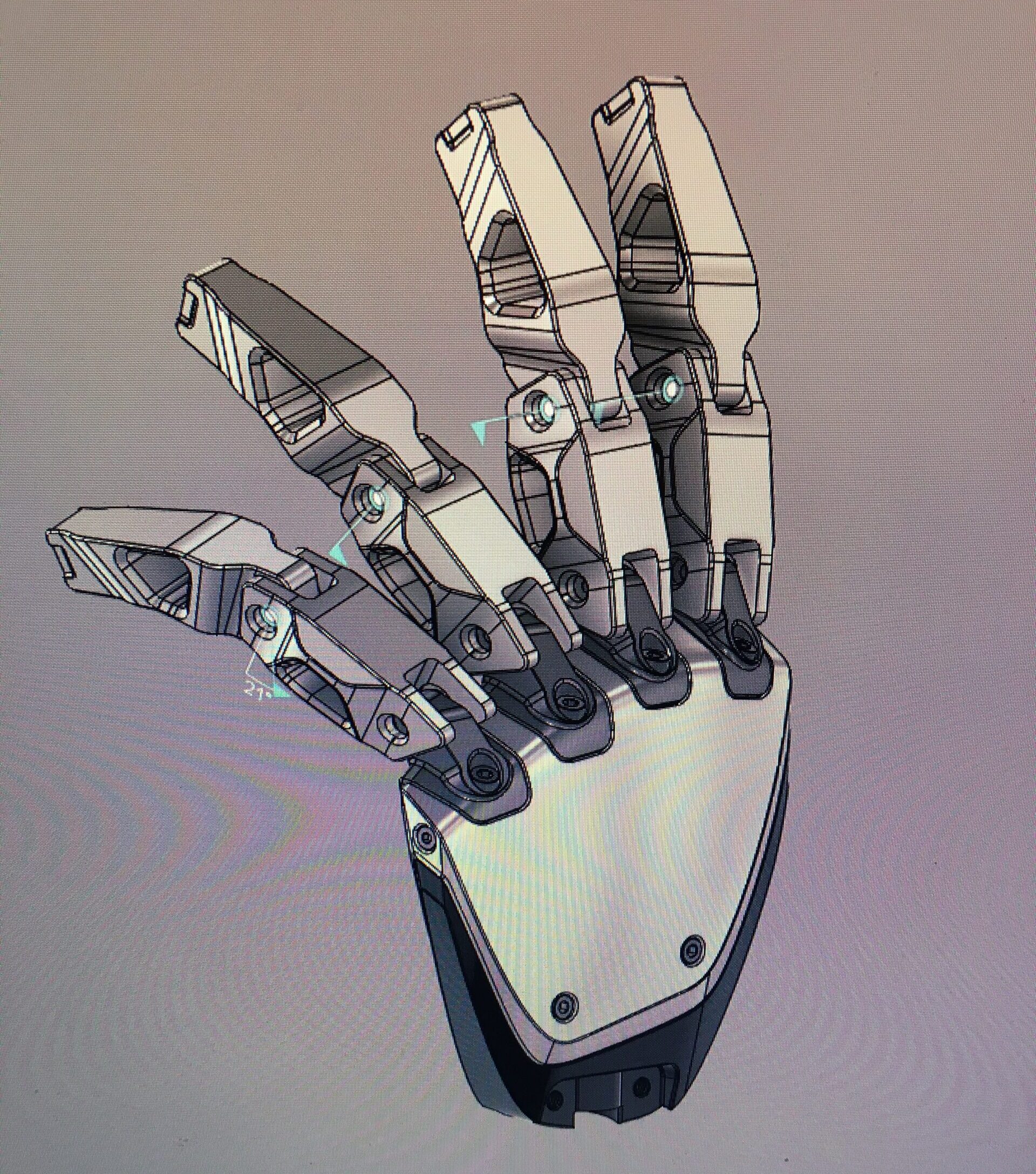

In the design process, we made a deliberate choice to focus on aesthetics that appealed to the users rather than trying to mimic the appearance of a human hand. Instead of aiming for hyper-realistic features, we embraced a bold, modern design that highlighted the functionality and uniqueness of the prosthetic. This approach resonated more with users who appreciated the futuristic look over a more traditional, lifelike appearance. By prioritizing style and innovation, we created a prosthetic that feels less like a replacement and more like a powerful, distinct tool—one that users could be proud to wear and excited to use every day.

A prosthetic hand focused on making a low cost, durable and easy to use alternative to high priced myoelectric options.

Design

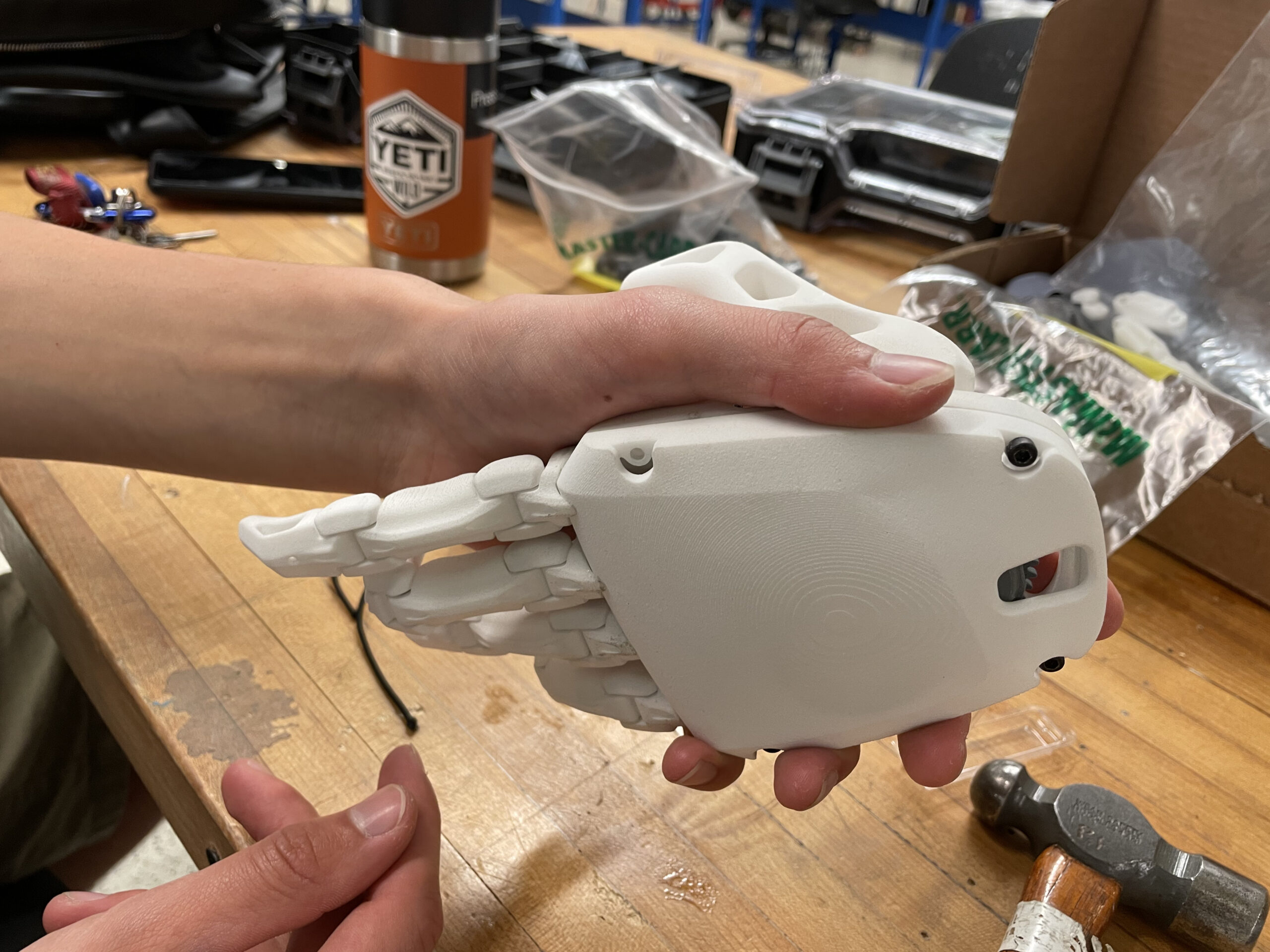

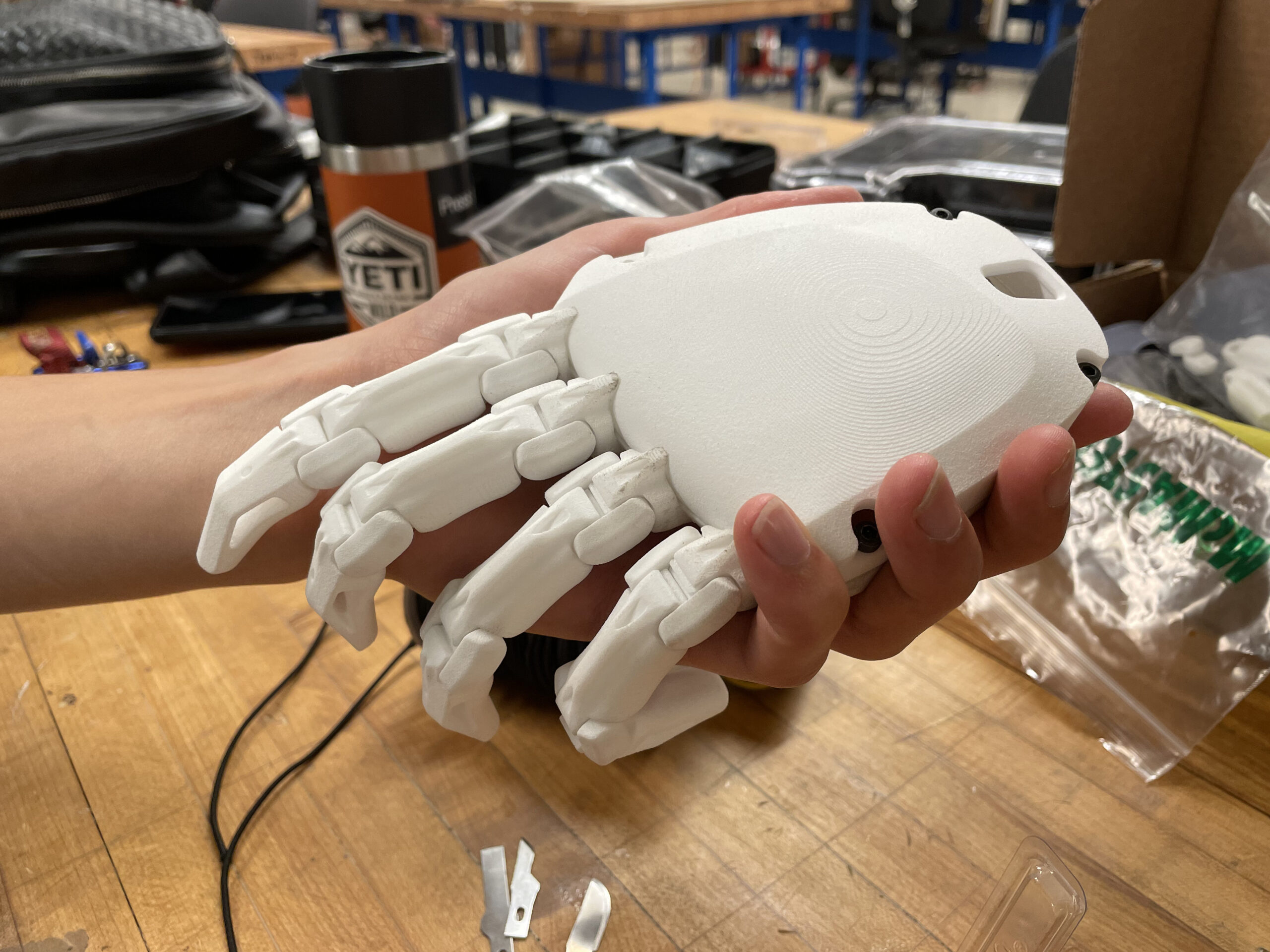

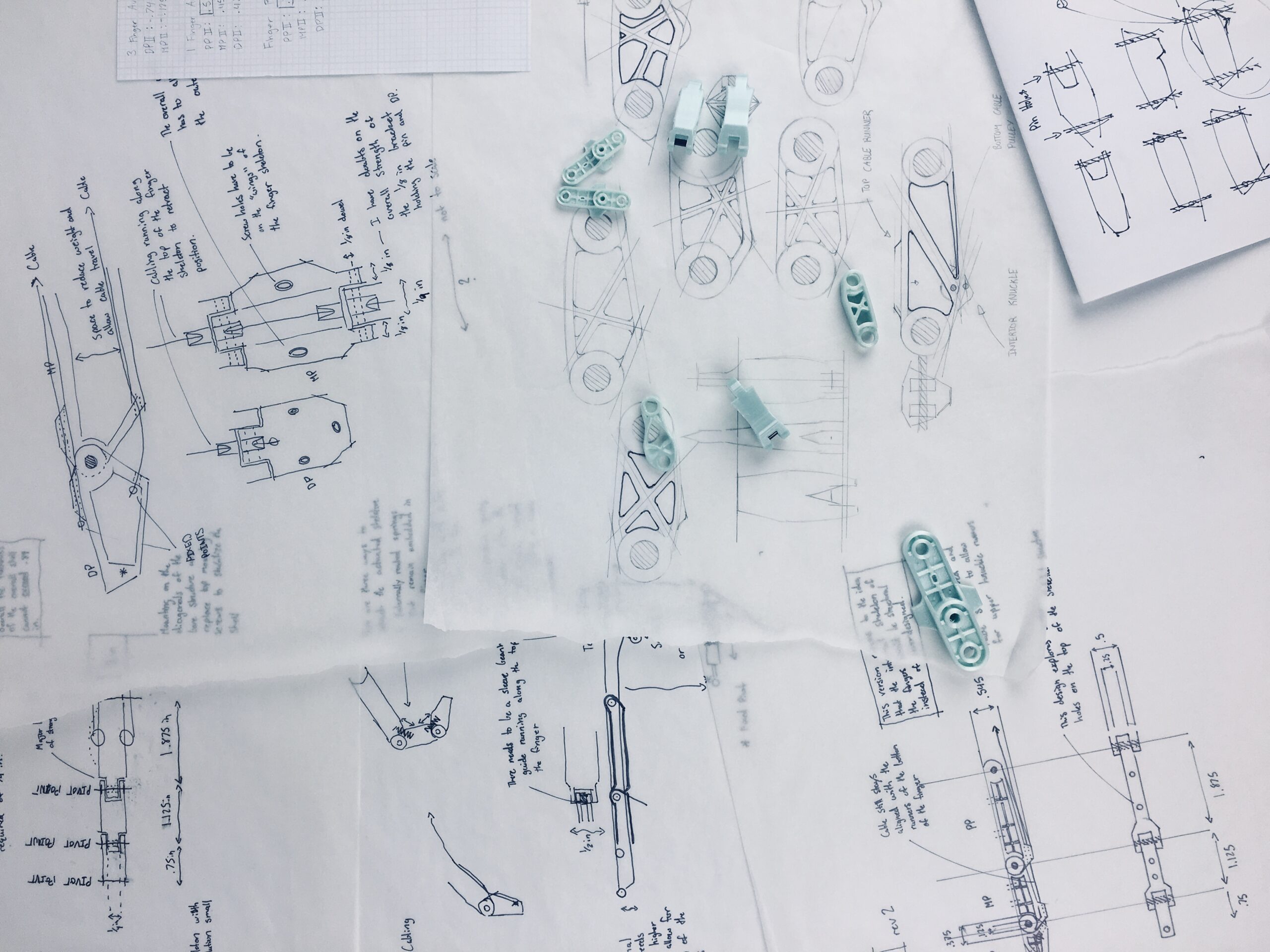

To keep the project cost-effective while ensuring user-centered design, we heavily relied on low-cost 3D printing to rapidly prototype and validate our designs with real users. This approach allowed us to quickly iterate on different forms and functionalities, getting immediate feedback from amputees before committing to more expensive production methods. By using 3D printing, we were able to make real-time adjustments, test various shapes, and refine the design based on user experience without incurring significant costs. This iterative process helped us stay agile and focused on delivering a prosthetic that was not only effective but also aligned with the needs of the amputees.

These design cycles were quickly iterated on and went through many stages on how we could develop a chassis that was robust enough for day to day tasks but also cheap. Since the goal of the hand was to have something manufactured for under $5000, we relied mainly on SLS printing for the final outputs.

The AION hand, while not complete, shows that with some design intent and future manufacturing methods it is possible to create a mechanical hand for amputees that is not as expensive as a car.

Every amputee deserves access to an advanced prosthetic hand at an affordable cost—it should be a human right. Right now, such accessible solutions don’t exist, leaving many without the tools they need for a full life.

MECHANICS AND NATURAL RATIOS OF LINKAGES

EARLY SKETCHING

Position

Our goal was to revolutionize prosthetics by making high-quality, advanced hands accessible to everyone. By combining innovative design with affordable materials, we’re challenging the status quo of expensive, limited options. This project isn’t just about creating a product—it’s about empowering amputees and ultimately the customer.

CONCEPT AION MATERIALITY

CONCEPT AION MODULAR FINGERS

AION. The future of prosthetics.